|

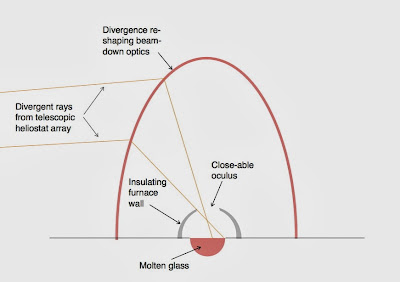

| All-glass, glass-making solar furnaces can be built up starting from a small seed. |

When we tap power from a solar furnace (which is really what CSP power towers are,) we are tapping power from a thing that can make other things. When the day comes that solar furnace energy is cost competitive with coal for boiler-temperature heat, it will already be a factor of two or three times cheaper than any other source of high-temperature heat for making things. The economics of certain materials will be revolutionized by the availability of cheaper high-temperature heat, none more so than glass.

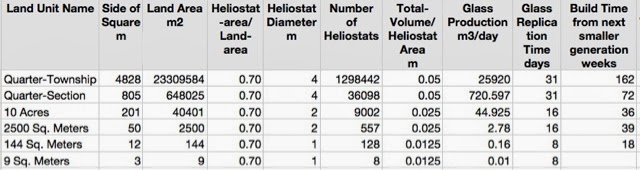

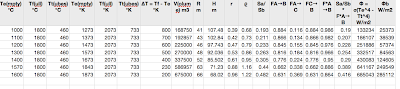

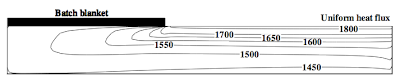

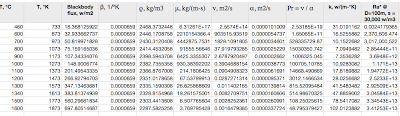

Laurent Pilon et al. studied thermal transfer in a glass-making furnace that produced 3.35 kg/s of soda-lime glass, with a heat transfer from the combustion space to the melt of 8.3 MW. Thus the energy intensity of this portion of the glass making process is (8,300,000 J/s) / (3.35 kg/s) = 2.5 E6 J/kg. The room temperature density of soda-lime glass is 2600 kg/m3, so, ignoring additional heat requirements in the annealing, the energy intensity of finished glass is 6.4 E9 J/m3.

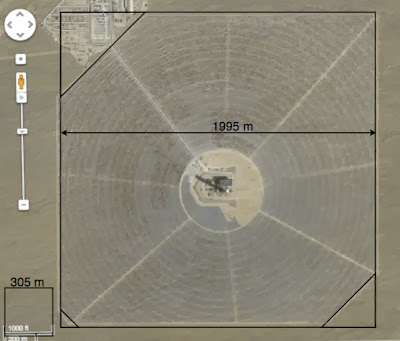

The solar generating unit Ivanpah 1, produces 126 MWe at a 32% capacity factor, thus averaging 40 MWe over the course of 24 hours. At a conversion efficiency of 0.40, Ivanpah 1 must be producing thermal power of 40 MWe / (0.40 MWe/MWth) = 100 MWth = 1.0 E8 J/s .

Therefore, Ivanpah 1, relieved of its power-generating duties, could make glass at the rate of (1.0 E8 J/s) / (6.4 E9 J/m3) = 0.016 m3/s or 16 liter/s.

Ivanpah 1 has 53,527 heliostats each with a mirror area of 15 m2, giving a total mirror area of 803,000 m2.

Now comes the guessing part: if a solar furnace is made entirely of glass, and the total volume of glass is pro-rated to the heliostat mirror area, how thick will the layer be? I'm going to say 5 cm (0.05 m.) On that basis, in making the glass for an Ivanpah 2, Ivanpah 1 must make (.05 m) * (803,000 m2) = 40,000 m3 of glass.

At 16 liter/s (0.016 m3/s), that task will occupy Ivanpah 1 for (40,000 m3) / (0.016 m3/s) = 2.5 E6 s = 700 h = 29 days.

Making the glass for two copies of itself, an all-glass Ivanpah 1 solar furnace would be offline for just two months! (Of course there's a lot more to it than just making glass, but that other stuff is not Ivanpah 1's responsibility.)

Suppose each solar furnace makes the glass for two copies of itself and only afterwards gets about the business of full-time power generation. The glass for two units can be made in 2 months, but completing them will take longer, let's say it takes an additional 10 months. Setting the year clock to n = 0 when the first solar furnace starts making glass, and taking a census of solar furnaces annually, the census series will be:

1, 3, 7, 15, 31, 63, 127, 255, 511… = 2

n+1 - 1

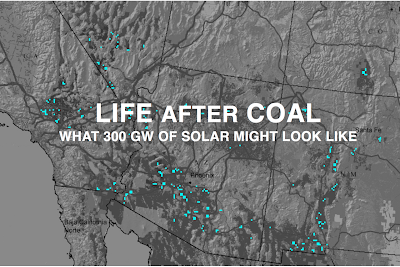

Replicating to 300 units takes less than 8 years.

That said, it might make more sense to do things the old-fashioned way, using a special-purpose solar furnace sited near the best raw materials. An individual glass-making unit would need 300 months (25 years) to make glass for 300 units, so 3 specialized glass-making furnaces would be needed to make 300 units in about 8 years.

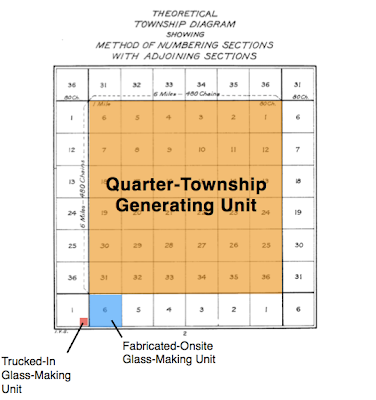

The quarter-township units proposed in an earlier post are considerably larger than Ivanpah 1, their thermal power is

(1000 MWe) * ( 0.75 capacity factor) / (0.40 MWe/MWth) = 1875 MWth,

which is comparable to the thermal power of a 1 GWe coal-fired plant.

That is 1875 / 100 = 19 times more thermal energy than Ivanpah 1 produces, so it yields 19 * 16 l/s = 300 liters of glass per second. If the glass layer thickness (0.05 m) is the same, the reproduction time will be the same as calculated above (4 weeks), but the mass flows are huge: 2,800 tons of glass per hour, 24/7. Put in terms of the 120-ton capacity of one railroad coal car, that would be 570 cars—or about five, 120-car unit trains per day. That is a mass flux is needed in two directions, carrying materials in and glass parts out.

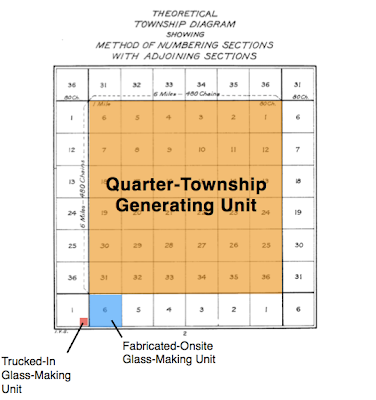

Such big mass flows need to be as short as possible. A "growing from an acorn" motto seems more appropriate than "dividing like yeast." Since a small unit can make in three years the glass for a unit 36 times larger than itself; and, since solar resource quality varies gradually over wide areas; it makes sense to site a relatively small, specialized glass-making unit where raw material resources are excellent, and let it slowly build the larger specialized power-generating unit. When the local area is considered built-out, the glass-making unit might be disassembled and relocated, or retired in-place to making spares.

To make a quarter-township solar generating unit, a one-section (one square mile) solar glass-making unit would need 9 months to make the glass; a quarter-section solar glass-making unit would need 36 months. Since it usually takes 3 to 4 years to build a conventional power plant, a quarter-section glass-making unit is probably about right.

The quarter-section glass-making unit could itself be built in 16 months by a 10-acre glass-making unit. If fabrication and assembly proceed just-in-time with the glass production, a quarter-township generating unit would be completed in 16 + 16 + 36 = 68 months (5.7 years) after the 10-acre unit starts producing glass.

In this way, the maximum mass flow, which occurs during the 36 months when the quarter-section glass-making unit is making parts for the quarter-township generating unit, amounts to 570/36 = 16 rail cars per day, but these trips are from local quarries and out to the adjoining, under-construction, heliostat field.

If the 10-acre (40,470 m2) unit can be slimmed down to a 2.5 cm glass layer—say, by using half-scale heliostats—then its mass is

40,470 m2 * (0.70 mirror/land ratio) * (0.025 m) * (2600 kg/m3) = 1800 tons

amounting to 15 rail cars to deliver it ready-to-assemble.

As a check: the trucked-in plant would make that much glass (15 rail cars) in just 2 weeks (being a slimmed-down, half-thickness design), so it can make about 1 rail car per day of glass. After successive multiplications of 16x (going up to a quarter-section, or 160 acres) and 36x (going up to a quarter-township, or 9 sections) the yield of the quarter-township unit should be (1 railcar/day) * 576 = 576 railcars/day, which checks against 570 rail-cars calculated above.

If it is necessary to reduce the freight still more, another factor of 16, down to a 2500 m2 land area (50 m x 50 m,) would just add 8 more months (since slimmed-down units replicate in just half a month.) The trucked-in weight now down to 110 tons. Another factor of 16, down to a 160 m2 land area (13 m x 13 m,) would add 8 months and reduce freight down to one load for a medium duty truck, 7 tons.