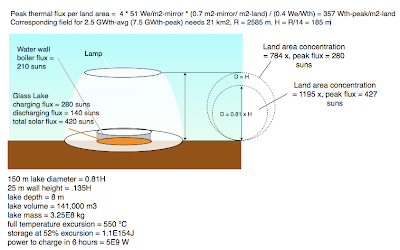

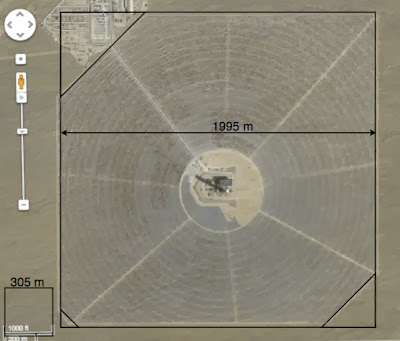

High-temperature, thermal buffer storage increases the capacity factor of a solar electric plant and thus reduces the cost of thermo-mechanical conversion and electricity generation and transmission. As power sources like wind and photovoltaic—which lack access to inexpensive energy storage—become more common in the utility mix, an increasing value of high-temperature thermal storage will be permitting time-shifting daily output to seek better electricity prices. Another value of buffer storage, which may or may not be minor, is reducing the thermal cycling of the expensive high-temperature conversion equipment. Here, I will only attempt to assess the first value, the value due to increased capacity factor

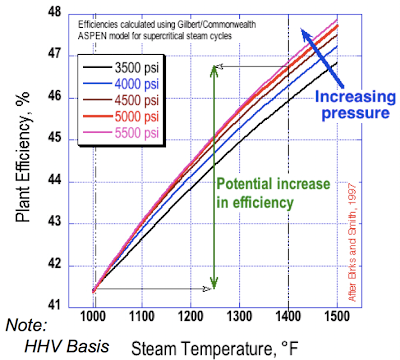

Dirk Pauschert in "Study of Equipment Prices in the Power Sector" estimates the cost of an 800 MW supercritical coal-fired power plant at $1960/kw (2008 US$). While that includes costs specifically associated with coal combustion, it also does not include the significant transmission costs associated with a remotely sited solar plant—so I will not apply a correction, $1960/kw it is.

I assume adding 20 hours of storage allows a solar plant to improve its capacity factor from 0.25 to 0.75 (without significant increased losses.) Thus a plant that would have needed 1 kw of turbine/generator capacity with no storage, only needs 0.33 kw of turbine/generator capacity with 20 hours of storage (i.e., having a capacity factor of 0.75 instead of 0.25, it has three times as long to generate the same kilowatt-hours.) That saves two-thirds of the original $1960 cost of the plant, a savings of $1313. With a heat-to-electricity conversion efficiency of 0.40, the thermal storage needed achieve that savings is:

(20 hours) * (0.33 kw

e) / (0.40) = 16.5 kw-hr

th

Given that two other sources of value were ignored, a conservative estimate for the value of thermal storage is:

($1313) / 16.5 kw-hr

th = $80 / kw-hr

th.

Quoting

an earlier post about thermal storage in high-purity glass melts:

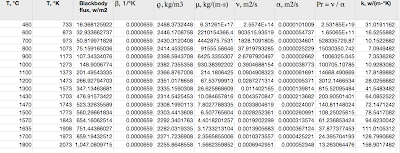

From Pilon et al., the specific heat, c, of molten glass between 1000 °C and 2000 °C is about 1231 J/kgK...

Another previous post found that the practical delta-T for molten glass storage (bounded by a practical maximum temperature for the insulated roof of the furnace and the need for intense radiative transfer to the boiler tubes) is 230 °C. So a 230 °K storage range stores 230 * 1231 = 283,000 J/kg.

Converting that storage density to kw-hr

th/t:

(283,000 J

th/kg) * (1000 kg/t) * (2.8 E-7 kw-hr

th/J

th) = 79 kw-hr

th/t

Thus the economic value of one ton of high-purity glass employed in this way is:

($80 / kw-hr

th) * (79 kw-hr

th/t) = $6,340 / t

This seemingly high value per ton is not out of line with more familiar high-temperature options.

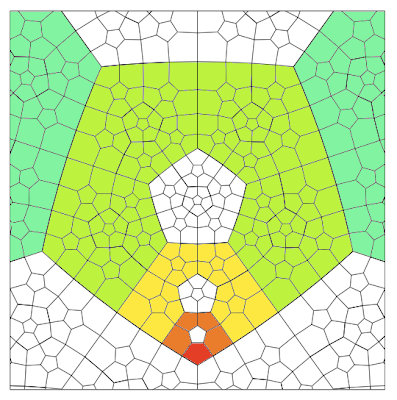

|

| Table comparing cost and performance of high-temperature thermal storage materials. Image quoted from Xiangyu Meng et al., "Theorectical Investigation of solar energy high temperature heat storage technology based on metal hydrides." |

For example, the table above quotes nitrate salts as costing $1700/t, and states that they store 77 kw-hr

th / m

3, or 41 kw-hr

th/t —about half as much thermal storage per ton—and at lower temperature than molten glass (which signifies lower conversion efficiency.)

To quote Reiner Haus et al. in "Assessment of high purity quartz resources,"

Beneficiation of raw quartz into refined high-purity products involves several refinement steps which need to be adapted to effectively minimise the specific impurities of the individual raw quartz feed to comply with stringent end-use specifications (Haus 2005). As a result, high purity quartz with total impurity levels less than 20 ppm may be achieved so creating a highly valuable raw material which commands up to 5 EUR/kg.

That is, 20 ppm high-purity silica is currently available at $7,000 / t.

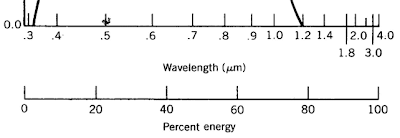

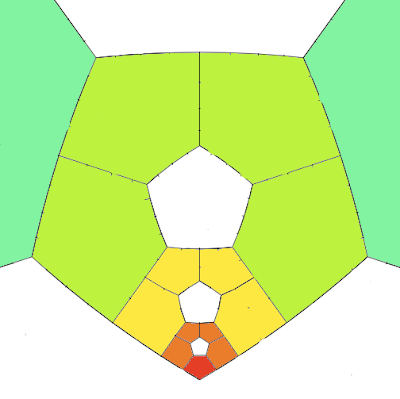

Optical attenuation in glass-melt solar storage is somewhat similar to attenuation in optical fibers, about which much is known. The spectral attenuation graph for silica fiber reproduced below, shows that, barring metallic ion impurities, there are two different sources of attenuation. At short wavelengths the attenuation is mostly due to Rayleigh scattering; at infrared wavelengths, most of the attenuation is due to OH impurities, and eventually, in the longer infrared, attenuation is due to the tail of the absorption Si-O bonds of the silica itself.

|

| Rayleigh scattering and OH absorption in silica optical fibers. Image quoted from Giusy Origlio, "Properties and Radiation Response of Optical Fibers: Role of Dopants." |

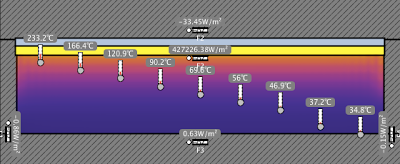

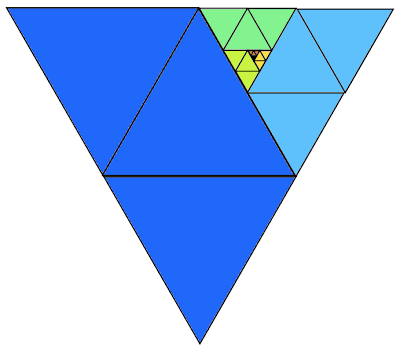

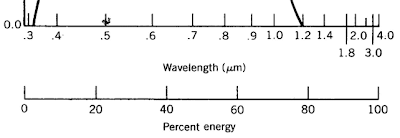

In glass-melt thermal storage we need much of the solar energy to penetrate deep into the melt to stir its lower half. We do not need particular wavelengths reach the depths. The figure below shows that about half of the energy in solar radiation is shorter than 0.75 microns—and thus more than half of solar energy lies in the region where attenuation is mainly due to Rayleigh scattering.

|

| Percentage of solar radiation shorter than a given wavelength. A wavelength distorted scale quoted from www.powerfromthesun.net . |

That is good news because Rayleigh scattering, which is due to thermal inhomogeneities in the glass matrix itself, depends on temperature not on purity. Thus the very difficult problem of reducing the "water peaks" caused by OH ions, which demands extreme purities in glass for optical fibers, does not arise in glass melt storage. For solar glass-melt thermal storage, the easier problem of reducing metallic ion impurities, Fe in particular, reigns instead.

Quoting

the Wikipedia article on Rayleigh scattering:

Rayleigh scattering is an important component of the scattering of optical signals in optical fibers. Silica fibers are disordered materials, thus their density varies on a microscopic scale. The density fluctuations give rise to energy loss due to the scattered light, with the following coefficient:[7]

where n is the refraction index, p is the photoelastic coefficient of the glass, k is the Boltzmann constant, and β is the isothermal compressibility. Tf is a fictive temperature, representing the temperature at which the density fluctuations are "frozen" in the material.

Fictive temperatures for silica glass range from 1373 °K to 1773 °K (1100 °C to 1500 °C); by comparison the temperature range in a glass-melt storage is 1840 °K to 2070 °K (1570 °C to 1800 °C). Since the dependence of scattering on absolute temperature is only linear, there should be about a 25% increase in Rayleigh scattering in a thermal storage glass-melt as compared to an optical fiber.

Since we are now utilizing only half the of solar spectrum to heat the bottom of the melt, short-wavelength attenuation in the melt can only be about 75 db/km, in other words, we need about half of the short wavelength solar energy needs to reach the very bottom of the glass melt. As the figure below shows, Rayleigh scattering only rises that level in the ultraviolet.

|

| Spectral attenuation of glass fiber materials showing short-wavelength Rayleigh scattering for silica. Quoted from Giusy Origlio, "Properties and Radiation Response of Optical Fibers: Role of Dopants." |

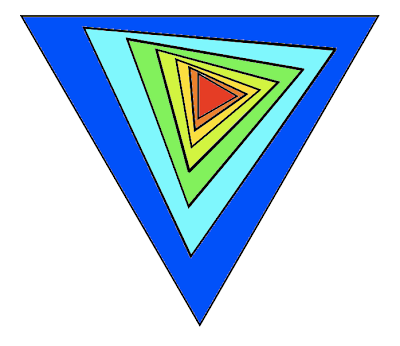

|

| Attenuation due to metallic ion impurities in optical fibers. Quoted from Murata, "Handbook of Optical Fibers and Cables." |

The chart above suggests that a concentration of about 60 ppb of Fe2+ could be tolerated in a glass-melt used for solar energy storage. That level of purity, 60 ppb, is still about 300 times the purity of the 20 ppm silica that is currently available at a price affordable for use as thermal storage.

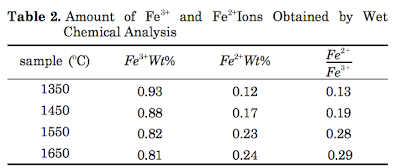

Absorption by iron depends on the oxidation state of the ion, the ferrous, Fe2+, or the ferric, Fe3+. It appears that the more oxidized state, Fe3+, might be preferable for solar energy storage, because of lower absorption. Quoting from Bahman Mirhadi and Behzad Mehdikhani,

"Effect of Batch Melting Temperature and Raw Material on Iron Redox State in Sodium Silicate Glasses":

Because iron has two redox states, Fe2+ and Fe3+, and these states have different colors, control of the redox condition during melting is important in adjusting the transmittance of glass in the wavelength regions of UV, visible light, and IR. When melted glass is placed in a reductive environment, the content of Fe2+ increases, and the glass turns bluish green because Fe2+ has a broad absorption band centered at 1050 nm. This absorption band is utilized in IR-cut glass such as cold-filtered glass which is produced under reductive conditions. When melted glass is placed in an oxidative environment, the iron in the glass is oxidized to the Fe3+ state and produces a yellowish color due to an absorption band which shows strong absorption below 380 nm that tails off towards longer wavelengths up to about 450 nm.

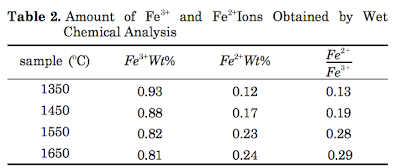

|

| Mirhadi and Mehdikhani found that the redox ratio, Fe+2/Fe3+, increases in the solidified glass with melt temperature, reaching a plateau at about 0.3. |

Mirhadi and Mehdikhani found that the redox ratio, Fe+2/Fe3+, increases in the solidified glass with melt temperature, reaching a plateau at about 0.3. If Fe3+ is indeed strongly preferable, then 180 ppb of total iron may be acceptable in a glass melt used for solar energy storage since only a third will be in the more absorbing Fe2+ redox state. That is still 100 times the purity of silica currently available at an acceptable price.